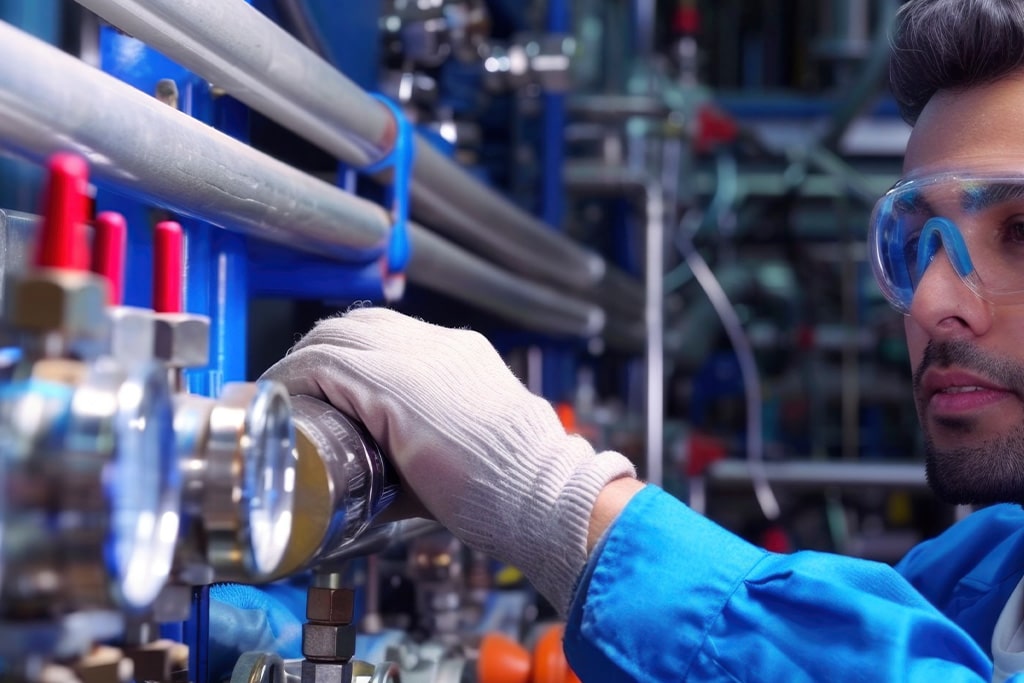

At Bama Technologies, we specialize in high-performance chemical solutions and system designs for critical metal surface treatments.

From degreasing and pickling to passivation, electropolishing, and anodizing, our services are engineered to enhance surface properties, maximize material life, and uphold the highest quality standards for precision components across aerospace, energy, petrochemicals, advanced manufacturing, and more.

With a strong focus on advanced system design and clean area solutions, we help organizations optimize the processing of critical components—ensuring superior durability, corrosion resistance, and operational excellence.